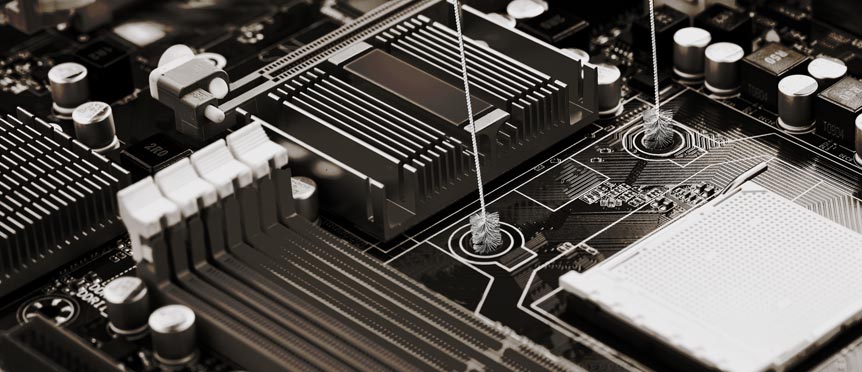

Motor and computer technology

Neat deburring is a key production step in the machine and computer industry. Precise functioning can only be guaranteed if reliable deburring has taken place. HK - KOTI twisted-in wire brushes are ideal for deburring gearboxes, injection pumps and carburettors. When machining cylinder and piston bearing surfaces, our HK - KOTI flexible brushes ensure a highly efficient fine ground surface finish. Abrasive spheres are anchored at the ends of the sturdy nylon bristles. These compact but inherently flexible brushes permit optimum adjustment to cylindrical, conical or oval drill holes. Our twisted-in wire brushes are also used for deburring computer motherboards. Wherever even rounding of edges, neat deburring and a perfect surface finish are required – our brushes precisely fulfil your needs in a wide range of individual variants.

These compact but inherently flexible brushes permit optimum adjustment to boreholes. However, HK - KOTI Flex brushes are capable of effortlessly machining not only cylindrical but also conical or oval boreholes. These brushes are also used to chamfer edges. The flexible contact pressure avoids cut, torn or folded metal. HK - KOTI Flex brushes are offered from a bore diameter of 4-118 mm with the following grain sizes: K.120-K.600.

Tube cleaning brushes are another type of twisted in brushes manufactured specifically for cleaning the inside of pipes for rust removal, cleaning and descaling operations. They are used predominantly for manual machining and in flexible shafts as well as stationary machines.

The wires are embedded in an elastic plastic compound, making them particularly aggressive with a long service life.

Ideally suited for deburring O-ring recesses, boreholes, for cleaning, smoothing and rust removal.

These brushes enable efficient and economical bushing of the blind hole base, while simultaneously processing the flanks. This makes for significant time savings. Simply let us know your requirements.

Diamond pipe brushes are steel wire brushes, with electrodeposited diamond grit, which will tackle any type of drill hole. Also suitable for hardened materials.

Due to their prolonged durability, electrodeposited diamond circular brushes are economical all-rounders when it comes to lightly rounding edges, removing persistent burrs or carrying out surface treatments.

For smoothing, cleaning casting seams and rubber-to-metal parts, for deburring. Rust removal, paint stripping.

For cleaning, deburring or polishing of small surfaces or small workpieces.

Shaft-mounted circular brushes are ideal for use in drilling machines, flexible shafts, pneumatic grinders and stationary machines. They are capable of machining wide-ranging different surfaces, particularly in difficult-to-access locations. These brushes are also used for smoothing, cleaning casting seams and rubber-to-metal parts as well as for light deburring work and for removing corrosion and paint.

Single ring brushes are available with different mounting bores and filler types, making them suitable for a variety of working widths. The brushes are particularly suitable for roughening and deburring as well as for removing oxide layers and paint.

Plastic encapsulated circular brushes are wire brushes vulcanised in plastic and come in a variety of Shore hardnesses and grades of wire, depending on the intended application.

End brushes are used wherever work is being undertaken with electrical or compressed air tools. They are indispensable in the production of vehicle bodies, vehicles and engines.

Rubberised end brushes are the aggressive alternative. They are distinguished by their ability to retain their shape and their outstanding surface stripping capacity. The appropriate Shore hardness can be chosen to suit the intended application.

Cup brushes with or without shaft are allround brushes used in angle grinders and machining centers for removal of varnish layers, scales and corrosion; also ideal for the treatment of welds and paling-board cleaning.

Bevelled disc brushes are a combination of circular and cup brushes. Thanks to their shape and threaded mount, they are ideal for hand-held angle grinders. They are particularly suitable for use on edges which are difficult to access.

Punched disc brushes are made to your specifications on CNC machines. In this way, it is possible to ensure the required processing reliability to the utmost extent.

For our encapsulated brushes, we use special synthetic resins to anchor the bristles to the disc. In this way, it is possible to make particularly dense, aggressive disc brushes with a variety of body materials.

These are used to remove fine welding splashes in different-to-access locations on gear components.