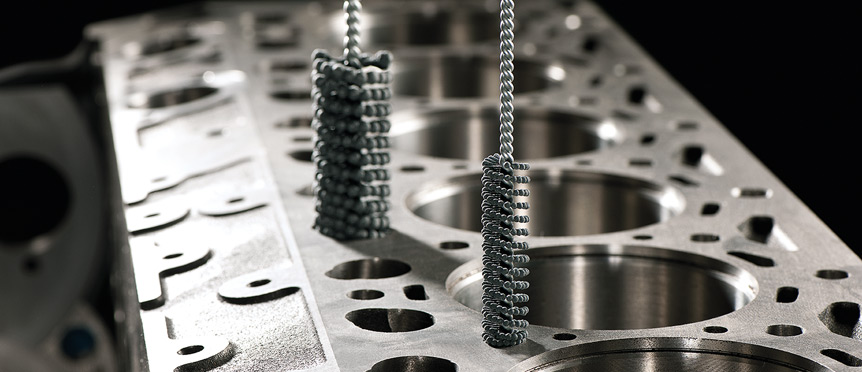

Drill hole deburring

Drill holes have to be deburred in countless different fields of application and sectors of industry. Here, precision, a high deburring quality and economy are paramount. HK - KOTI pipe brushes can be used to neatly and efficiently remove the edges, chamfers and splinters created during the machining or manufacturing process. Twisted-in wire brushes – whether cylindrical, conical, stepped or wing-shaped – are available in a wide range of designs in line with your preferences and your requirements. Flexible brushes can be used for the highly efficient machining of drill holes in steel, grey cast iron, aluminium and all customarily used non-ferrous metals. Special diamond brushes are used for the reliable removal of thick, tough burr formation.

These compact but inherently flexible brushes permit optimum adjustment to boreholes. However, HK - KOTI Flex brushes are capable of effortlessly machining not only cylindrical but also conical or oval boreholes. These brushes are also used to chamfer edges. The flexible contact pressure avoids cut, torn or folded metal. HK - KOTI Flex brushes are offered from a bore diameter of 4-118 mm with the following grain sizes: K.120-K.600.

Tube cleaning brushes are another type of twisted in brushes manufactured specifically for cleaning the inside of pipes for rust removal, cleaning and descaling operations. They are used predominantly for manual machining and in flexible shafts as well as stationary machines.

The wires are embedded in an elastic plastic compound, making them particularly aggressive with a long service life.

Ideally suited for deburring O-ring recesses, boreholes, for cleaning, smoothing and rust removal.

This type of twisted in brushes with their characteristic wing shape are particularly suitable for intensive cleaning of boreholes and inner surfaces due to their compact, highly dense filling. They are available with outside diameters from 5 mm.

Combi brushes feature a dense filling and are ideally suitable for cleaning threaded boreholes, and brushing edges and long-shaped recesses.

These brushes enable efficient and economical bushing of the blind hole base, while simultaneously processing the flanks. This makes for significant time savings. Simply let us know your requirements.

Diamond pipe brushes are steel wire brushes, with electrodeposited diamond grit, which will tackle any type of drill hole. Also suitable for hardened materials.

Shaft-mounted circular brushes are ideal for use in drilling machines, flexible shafts, pneumatic grinders and stationary machines. They are capable of machining wide-ranging different surfaces, particularly in difficult-to-access locations. These brushes are also used for smoothing, cleaning casting seams and rubber-to-metal parts as well as for light deburring work and for removing corrosion and paint.

Single ring brushes are available with different mounting bores and filler types, making them suitable for a variety of working widths. The brushes are particularly suitable for roughening and deburring as well as for removing oxide layers and paint.

Plastic encapsulated circular brushes are wire brushes vulcanised in plastic and come in a variety of Shore hardnesses and grades of wire, depending on the intended application.

End brushes are used wherever work is being undertaken with electrical or compressed air tools. They are indispensable in the production of vehicle bodies, vehicles and engines.

Rubberised end brushes are the aggressive alternative. They are distinguished by their ability to retain their shape and their outstanding surface stripping capacity. The appropriate Shore hardness can be chosen to suit the intended application.

This is a combination brush comprising a shaft cup brush and pipe brush. It is used for the simultaneous machining of a borehole and flat surface.

This is another combination brush comprising a plastic bonded cup brush and pipe brush. Its specific application is also the simultaneous machining of a borehole and the surrounding surface, for example to remove welding splashes.

Burraway deburring tools have a replaceable low-cost cutting blade which can be variably adjusted to remove different sizes of drilling residue. This universal deburring tool reliably removes burr on both sides of the borehole, while it only has to be applied from one side. The Burraway can be used both in CNC machines and in drilling machines, no special settings are required.

By means of the slotted configuration, the tool performs the deburring process under spring pressure. The integral cutting edges deburr the front and rear of the drill hole.

These simply structured electro-deposited deburring tools configured specifically for the purpose are available with or without an elastic extension. Diamond and Borazon deburring tools have a diameter of 1.5-12 mm and are available in spherical and cylindrical form with a longitudinal slot. They can be used for instance in vertical drilling machines or in machining centres in series production. This type of deburring tool is used on particularly hard parts.

Diamond ball-type deburring tools are particularly suitable for tough, hard materials and for use in areas which are difficult to get at, such as drill hole intersections. Ball diameters of e.g. 1.8 mm - 12 mm are possible. Special purpose diamond tools can be supplied to order.

Flap grinders from HK - KOTI adjust perfectly to the contours of the workpiece being machined due to their flap-shaped lamellae. Flap grinders are used for fine grinding work in tool and mould building for machining difficult-to-access surfaces in container and plant construction applications and for machining fittings made of non-ferrous and light-alloy metals.

Flap wheels from HK - KOTI are the ideal tools for surface machining. They remove rough unevenness, achieve a homogeneous grinding pattern on large-scale surfaces and contours, and are used for tasks such as ultra-fine grinding as a preliminary step ahead of highgloss polishing.

Abrasive fleece tools are particularly suited for dry and wet operation. They are used for cleaning and matt finishing plastics, for descaling metal surfaces and for achieving a surface finish.